Autotherm - History of the Hammant and Morgan Duette.

Hammant and Morgan Duette - History and Development

The original (first generation) Duette was produced in about 1959, by Hammant and Morgan, at Handem House in Wealdstone, Harrow, which is just North of London.

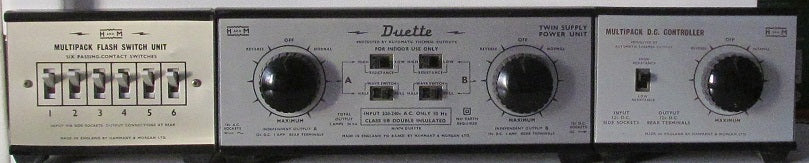

First generation Duettes are easily identified by the black control panel.

The original H & M product line up did not include a two channel controller as such, even though the word 'Multipack' was used as early as in the 1957-58 in the 'H & M Power Control' brochure.

In (or around) 1965 the second generation Duette arrived.

This is also when it became a 'Class 2' appliance, double insulated, dispensing with the need for an earth wire, and complying with the latest stringent UK

and worldwide safety requirements.

This controller can be identified by the silver face panel.

By 1965 Hammant and Morgan had moved into new premisies known as Handem Works a few miles north, in St Albans Rd, Watford.

In 1967 the lastest (third generation) Duette arrived.

This became the definitive twin track controller and has (arguably) never been bettered.

Sometimes referred to as the lowline, to differentiate it from the previous H & M products, which were higher in profile.

Solidly built in pressed steel, the Duette conformed and integrated with the lastest 'Multipack' series of H & M controllers.

Over the production run of almost twenty years, externally it does not appear to change very much, although the patterns did vary as small improvements were made.

The finish of the controllers changed several times too, some units were painted and some powder coated.

Looking at the Duettes still in use (and there are very many) the colours vary from slate to anthracite, and several shades in between.

Some were finished with a Hammerite type covering, giving an orange-peel type texture. Others have a powder-coating type finish.

Internally there has only been one significant change and that was the replacement of the selenium rectifers with silicon bridge rectifier assemblies.

This change certainly did not seem to impact the reliability of the units - often called bulletproof, they certainly remain almost indestructable.

Very sadly the manufacture of the Duette, along with other Hammant and Morgan transformers ceased in The UK in about 1985 when Hornby acquired the brand name to use on there own products which were are largely made in China.

It is hard to see the H & M controllers disappearing anytime soon, as the design, and over-engineering which was applied to them made them incredibly robust.

The main signs of ageing being the paintwork which, especially on models which have been kept in a less than ideal environment, can start to flake, allowing oxygen

to start to rust the case..

FAQs Frequently Asked Questions

What is the purpose of the full/half wave switch ?

The full/half wave switch on the Duette, Clipper and several other H & M controllers can provide better low speed control for some motors.

It works by only letting half rectified power through to the track. It is sometimes called 'Pulse-Power'.

By selecting 'Full Wave' rectification a smoother supply is provided.

Caution! Some types of motor have a tendency to run at a high temperature when half wave is selected.

What happened to Hammant and Morgan ?

In the mid 1980s Hornby acquired the company name and manufacturing in the UK stopped. The H & M identity was used on Hornby controllers which are made in Asia.

Wander Plugs

All Hammant and Morgan Multipack controllers use the same size (3mm) banana plugs to access uncontrolled outlets of 16v ac or 12v dc.

Wander Plugs can be found here.

Where can I download an instruction book for my Hammant and Morgan controller ?

You can't !

H & M products were never provided with an instruction book as such, however, units (including Duettes) were supplied with a small page of 'Operating Instructions' one is reproduced below.

What is an Autotherm ?

Autotherm is the proprietory name given to the bi-metal strip found in Hammant and Morgan controllers (and many other durable model railway controllers of the time'

.

It can also be described as a self-resetting overload protection device.

It simply protects your controller from potential damage when a short circuit occurs, such as a metal object falling accross the rails. or a faulty motor trying to draw excessive current.